Product Description

Quick Details

Condition: New Type: Wood Chipper

Use: Make wood and branches in chips Power Type: Tractor PTO driven

Production Capacity: 8-9CBM/H Place of Origin: ZheJiang China (Mainland)

Brand Name: ForestKing Model Number: TH-8

Dimension(L*W*H): Packing size 1150mmx9/WFA516)

2. DURABLE CHROMIUM CR-12 BLADE

3. DUAL ROTATING IN-FEED ROLLERS

4.8-9CBM/H EFFICIENCY

ForestKing HYDRAULIC AUTO FEED WOOD CHIPPER WITH DUAL ROTATING IN-FEED ROLLERS

Features:

3PL wood chipper, driven by Ttractor PTO

Cutting diameter size 1cm-25cm, up to 8 inch

8-9CBM/hour cutting capacity

Discharge hood can rotate in 360 degrees

Feeding system: Mechanical roller feeding or hydraulic motor feeding optional

Blade material: Durable Chromium CR-12

CE certificate

NEW ForestKing 2013 FEATURES INCLUDE:

6.25″ DIAMETER HARDENED STEEL COMMERCIAL STYLE IN-FEED ROLLERS–ForestKing EXCLUSIVE

NEW DUAL EDGE REVERSIBLE FLYWHEEL KNIVES–ForestKing EXCLUSIVE

27-HOLE FLYWHEEL VETILATION–ForestKing EXCLUSIVE

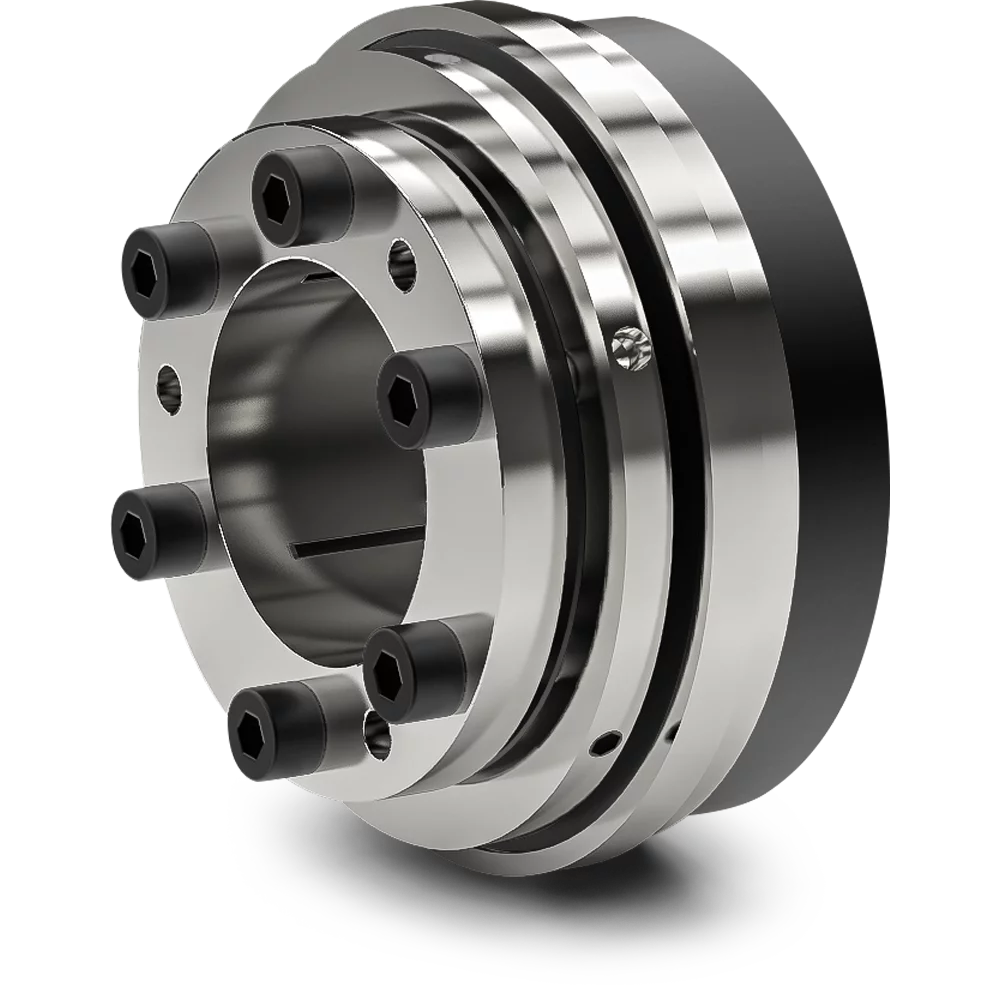

AUTOMATIC BELT TENSIONER–ForestKing EXCLUSIVE

EASY SWIVEL DISCHARGE CHUTE

ADJUSTABLE BED (ANVIL) KNIFE

2 YEAR WARRANTY

200 LB. FLYWHEEL- IDEAL WEIGHT

2″ (50MM) MAIN SHAFT

HEAVY DUTY CAST STEEL BEARING HOUSINGS

MAIN SHAFT SUPPORTED BY 3 BEARINGS

SELF CONTAINED HYDRAULIC SYSTEM

VARIABLE SPEED DUAL HYDRAULIC INFEED MOTORS

FULLY ADJUSTABLE INFEED ROLLER TENSION SPRINGS

WEIGHT 990 LBS.

TRUE 8″ X 8″ INFEED OPENING

3/8″ THICK FLYWHEEL HOUSING

EASY KNIFE ACCESS PANELS

HEAVY DUTY COGGED 17MM DRIVE BELTS

SAFETY AUTO FEED STOP BAR

HANDY FEED ROLLER ASSIST HANDLE

RUST RESISTANT POWDER COAT FINISH

CLEAR VINYL BAFFLE

MACHINE 90% ASSEMBLED CHINAMFG DELIVERY

Usage:

1. The small chips made by the wood chipper can be used for animal bedding, for the forestry and

Soil protecting, for new energy making, for compost and for charcoal.

2. Some customers use their colored garden waste chips, cover the soil and made the garden

Beautiful; Some of them use the garden waste chips in the fireplace.

| Technical details of PTO driven model Wood Chipper | ||

| Model | TH- 8 | TM- 8 |

| Max. Dia. of Feeding | 8” | |

| POWER | Tractor (18~100hp, 540/720rpm) | |

| Diameter of Chipper Disk | 600mm | 600mm |

| Turning Speed of Chipper Disk | 1080rpm/1410rpm | |

| Feeding System | Hydraulic Feeding, | Feeding by Worm Reduction |

| Adjustable Speed, | Gear(4mm/s) | |

| Stop-Reverse-Forward Function | Only CHINAMFG Function | |

| Blade material | Durable Chromium CR-12 |

|

| Sawdust Measurement | Thickness<4mm | |

| Rotation Angle of Discharge Spout | 360 | |

| Weight | 450kg(990LBS) | 420kg(930LBS) |

| Working Efficiency | 8~9m 3 /h | 6~9m 3 /h |

| Volume of TANK | 26L | / |

| PACKAGE DIMENSIONS (L×B×H) | 1150×900×1300 (mm) | 1150×900×1300 (mm) |

| 20GP/40HC container | 24unit/52units | 24units/52units |

/* January 22, 2571 19:08:37 */!function(){function s(e,r){var a,o={};try{e&&e.split(“,”).forEach(function(e,t){e&&(a=e.match(/(.*?):(.*)$/))&&1

| Certification: | CE, ISO |

|---|---|

| Max. Dia. of Feeding: | 8′′ |

| Power: | Tractor (18~100HP, 540/720rpm) |

| Turning Speed of Chipper Disk: | 1080rpm/1410rpm |

| Blade Material: | Durable Chromium Cr-12 |

| Sawdust Measurement: | Thickness<4mm |

| Samples: |

US$ 1260/Piece

1 Piece(Min.Order) | |

|---|

| Customization: |

Available

|

|

|---|

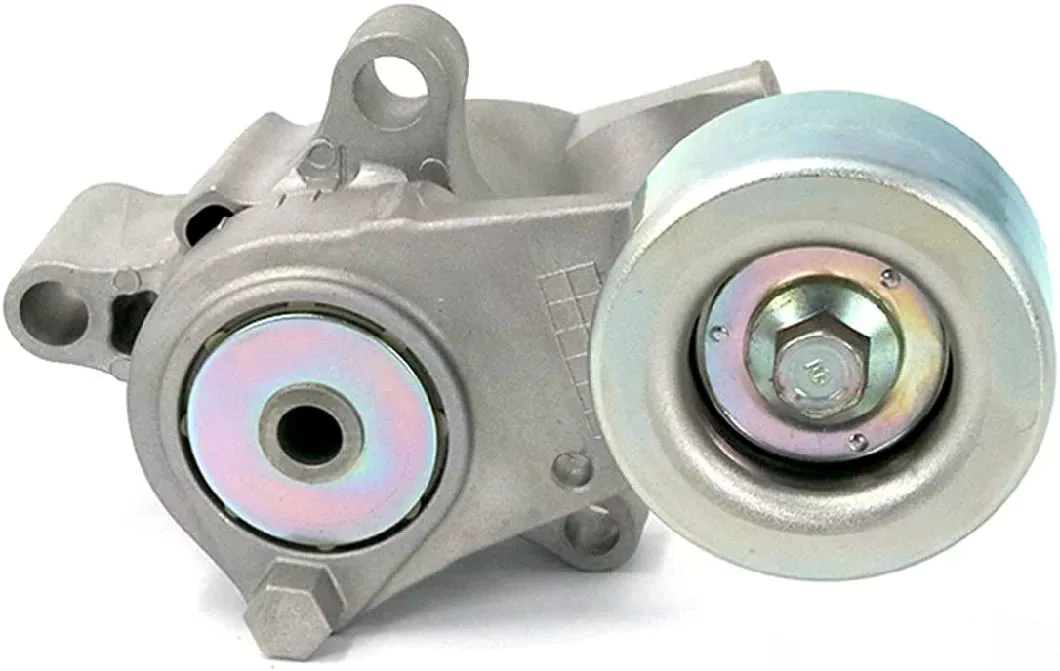

Are there aftermarket upgrades available for tensioner rollers to improve their functionality?

Yes, there are aftermarket upgrades available for tensioner rollers that can improve their functionality and performance. Aftermarket upgrades offer alternatives to the original equipment manufacturer (OEM) tensioner rollers, providing enhanced features, materials, and design. Here’s a detailed explanation of aftermarket upgrades for tensioner rollers:

1. High-Performance Materials:

Aftermarket tensioner rollers often utilize high-performance materials that offer improved durability, heat resistance, and wear characteristics compared to standard OEM rollers. These materials may include advanced polymers, reinforced composites, or specialty alloys. Upgrading to tensioner rollers with high-performance materials can enhance their functionality by increasing their lifespan and performance under demanding operating conditions.

2. Upgraded Bearing Systems:

Bearing systems in tensioner rollers can be upgraded with higher-quality bearings or specialized bearing designs. Improved bearing systems can offer smoother operation, reduced friction, and increased load-bearing capacity. Upgraded bearing systems contribute to improved functionality by reducing noise, vibration, and wear, and enhancing overall performance and reliability.

3. Damping Mechanisms:

Some aftermarket tensioner rollers feature enhanced damping mechanisms to reduce belt noise and vibration. These damping mechanisms can include rubberized coatings, silicone inserts, or advanced damping materials. Upgrading to tensioner rollers with improved damping capabilities can enhance functionality by providing a quieter and smoother operation, improving the overall driving experience.

4. Tension Adjustment Features:

Aftermarket tensioner rollers may offer additional features for tension adjustment. These features can include adjustable tension springs, mechanical or hydraulic tensioners, or built-in tension adjustment mechanisms. Upgraded tension adjustment features allow for fine-tuning of belt tension to meet specific performance requirements, optimizing functionality and performance under varying load and operating conditions.

5. Performance-Enhancing Designs:

Aftermarket tensioner rollers may incorporate performance-enhancing design elements. These designs can include optimized pulley profiles, improved belt contact surfaces, or modified geometries for better belt tracking. Performance-enhancing designs contribute to improved functionality by reducing belt slippage, improving power transfer efficiency, and minimizing wear on the belt and other components.

6. Enhanced Durability:

Aftermarket tensioner rollers may offer enhanced durability features to withstand demanding conditions. These features can include reinforced construction, corrosion-resistant coatings, or additional protection against contaminants. Upgrading to tensioner rollers with enhanced durability can enhance their functionality by reducing the risk of premature failure, extending their lifespan, and improving overall system reliability.

7. Compatibility and Fitment:

Aftermarket tensioner rollers are designed to be compatible with specific vehicle makes and models. They are engineered to match the original specifications and fitment requirements, ensuring proper installation and functionality. Upgrading to aftermarket tensioner rollers that are compatible with the vehicle’s belt system promotes optimal functionality and performance.

8. Manufacturer Reputation and Quality:

When considering aftermarket upgrades for tensioner rollers, it is important to choose reputable manufacturers known for their quality products. Selecting aftermarket tensioner rollers from trusted manufacturers ensures that the upgrades will provide the desired functionality and performance improvements, backed by reliable engineering and manufacturing processes.

In summary, aftermarket upgrades for tensioner rollers offer various enhancements to improve their functionality and performance. These upgrades can include high-performance materials, upgraded bearing systems, damping mechanisms, tension adjustment features, performance-enhancing designs, enhanced durability, and compatibility with specific vehicles. Choosing aftermarket upgrades from reputable manufacturers can provide reliable improvements to the functionality of tensioner rollers, contributing to enhanced belt system performance and overall vehicle drivability.

How do tensioner rollers contribute to reducing wear and increasing the lifespan of belts?

Tensioner rollers play a vital role in reducing wear and increasing the lifespan of belts in various applications. They offer several key contributions in achieving these objectives:

1. Maintaining Proper Belt Tension:

Tensioner rollers help maintain the optimal tension in belts throughout their operation. Proper tension is crucial for efficient power transmission and preventing belt slippage. When belts operate under inadequate tension, slippage can occur, leading to increased wear on the belt and associated components. Tensioner rollers ensure that the belts remain appropriately tensioned, reducing wear and extending their lifespan.

2. Absorbing Belt Vibrations:

Vibrations can occur in belt drive systems due to imbalances, misalignments, or variations in load. These vibrations can accelerate belt wear by causing friction and excessive flexing. Tensioner rollers are designed to absorb and dampen vibrations, minimizing their impact on the belt. By reducing vibrations, tensioner rollers help to decrease wear and prolong the life of the belt.

3. Distributing Tension Evenly:

Tensioner rollers distribute tension more evenly along the length of the belt. They help prevent localized areas of excessive tension, which can lead to premature wear and belt failure. By ensuring a more uniform distribution of tension, tensioner rollers contribute to reducing wear and extending the lifespan of belts.

4. Compensating for Belt Stretch:

Over time, belts can stretch due to the mechanical stresses they experience during operation. Belt stretch can result in reduced tension and compromised power transmission. Tensioner rollers are designed to compensate for belt stretch by applying additional tension to maintain the desired level of belt tension. This compensation helps to prevent belt slippage, wear, and premature failure, thereby increasing the lifespan of the belt.

5. Reducing Belt Misalignment:

Proper belt alignment is essential for minimizing wear and optimizing belt life. Tensioner rollers assist in maintaining belt alignment by exerting consistent pressure on the belt and guiding it along the desired path. By reducing belt misalignment, tensioner rollers help prevent edge wear, side-loading, and premature belt failure.

6. Providing Belt Support:

Tensioner rollers provide support to the belt, especially in longer spans or applications with heavy loads. They help prevent belt sagging and excessive flexing, which can lead to accelerated wear and reduced belt life. By offering support, tensioner rollers contribute to minimizing wear and increasing the durability of the belt.

7. Facilitating Belt Tracking:

Proper belt tracking is crucial for belt longevity and performance. Tensioner rollers aid in maintaining belt tracking by applying controlled pressure and guiding the belt along the intended path. By promoting accurate belt tracking, tensioner rollers help prevent edge wear, rubbing, and premature belt failure.

8. Minimizing Belt Slippage:

Belt slippage can occur when there is insufficient tension or excessive loads in the system. Tensioner rollers help maintain the necessary tension in the belt, ensuring a secure grip between the belt and the pulleys. By minimizing belt slippage, tensioner rollers reduce wear, heat generation, and premature belt failure.

In summary, tensioner rollers contribute significantly to reducing wear and increasing the lifespan of belts by maintaining proper tension, absorbing vibrations, distributing tension evenly, compensating for belt stretch, reducing belt misalignment, providing belt support, facilitating belt tracking, and minimizing belt slippage. These contributions help optimize the performance, efficiency, and longevity of belt drive systems in various applications.

In what types of vehicles or machinery are tensioner rollers commonly used?

Tensioner rollers are commonly used in a variety of vehicles and machinery where belt drive systems are employed. Here’s a detailed explanation of the types of vehicles and machinery in which tensioner rollers are commonly found:

1. Automobiles:

Tensioner rollers are extensively used in automobiles, including passenger cars, SUVs, and light trucks. They are an integral part of the engine’s accessory drive system, where they help maintain proper tension in the belts that drive components such as the alternator, water pump, power steering pump, and air conditioning compressor. Tensioner rollers contribute to the reliable operation of these accessories and play a crucial role in the overall performance of the vehicle’s engine.

2. Commercial Vehicles:

Tensioner rollers are also commonly utilized in commercial vehicles, such as heavy-duty trucks, buses, and delivery vans. These vehicles often have larger and more complex engine systems that require multiple belts to drive various accessories. Tensioner rollers help ensure proper tension in these belts, allowing for efficient power transmission and reliable operation of the engine accessories.

3. Agricultural Equipment:

In the agricultural sector, tensioner rollers find widespread use in various types of machinery, including tractors, combine harvesters, and other farm equipment. These machines often rely on belt drive systems to power critical components like the water pump, alternator, hydraulic systems, or conveyor belts. Tensioner rollers play a vital role in maintaining optimal belt tension, enabling proper functionality and efficient operation of agricultural machinery.

4. Construction and Heavy Machinery:

Tensioner rollers are employed in construction and heavy machinery, such as excavators, loaders, bulldozers, and cranes. These machines utilize belt drive systems to power auxiliary components like hydraulic pumps, generators, or air compressors. Tensioner rollers help ensure that the belts remain properly tensioned, allowing for reliable power transmission and smooth operation of the machinery in demanding construction or industrial environments.

5. Industrial Equipment:

In various industrial applications, tensioner rollers are used in machinery and equipment such as manufacturing systems, conveyor systems, packaging machines, printing presses, and textile machinery. These systems often rely on belt drive mechanisms to transfer power between different components. Tensioner rollers assist in maintaining the desired tension in the belts, ensuring efficient power transmission and reliable operation of industrial equipment.

6. Recreational Vehicles and Boats:

Tensioner rollers are also found in recreational vehicles (RVs) and boats. RVs may have belt drive systems for powering components like air conditioning units, generators, or water pumps. Tensioner rollers help maintain belt tension in these systems, ensuring reliable operation during camping or travel. In boats, tensioner rollers can be used in propulsion systems or to drive accessories like water pumps or alternators, contributing to the smooth and efficient operation of marine engines.

7. Other Applications:

Additionally, tensioner rollers may be utilized in various other applications where belt drive systems are employed. This can include power tools, industrial pumps, compressors, agricultural machinery attachments, and more. Tensioner rollers are versatile components that find application in diverse machinery and equipment that rely on belt drives.

In summary, tensioner rollers are commonly used in vehicles and machinery such as automobiles, commercial vehicles, agricultural equipment, construction and heavy machinery, industrial equipment, recreational vehicles, boats, and other applications where belt drive systems are utilized. Their presence ensures proper tension in belts, contributing to efficient power transmission, reliable operation, and optimal performance in a wide range of equipment and machinery.

editor by CX 2024-03-29

China wholesaler Wire Rope Double Drum Crane for Shaft Lifting

Product Description

Wire Rope Double Drum Crane for Shaft Lifting

Introduction:

Mine hoist can be divided into 2 kinds; 1 kind is JKE series single rope mining hoist and the other is Multi-rope friction hoist.

This series mine hoist including 2m-5m single tubular and double tubular types, and can be used for mining hoist, personnel lifting and material and equipment descending from vertical shafts or inclined shafts of coal, metal and nonmetal ores.

JK mine hoist is mainly used in inclined roadways and wells of coal mines, metal mines and non-metal mines to hoist or lower personnel and materials.

Technical parameters:

| Model | Drum | Tension PF |

Tension Differe |

Rope Diameter |

Lift height (m) | Max Speed |

Reduce speed ratio |

Motor Speed |

||||||

| Number | Dia | Width | 1-layer | 2-layer | 3-layer |

|||||||||

| m | KN | mm | m | m/s | r/min | |||||||||

| JK-2×1.5/20 | 1 | 2.0 | 1.5 | 62 | 24 | 305 | 650 | 1571 | 5.2 | 20.0 | 1000 | |||

| JK-2×1.5/31.5 | 31.5 | |||||||||||||

| JK-2×1.8/20 | 1.80 | 375 | 797 | 1246 | 20.0 | |||||||||

| JK-2×1.8/31.5 | 31.5 | |||||||||||||

| JK-2.5×2/20 | 2.5 | 2.00 | 83 | 28 | 448 | 945 | 1475 | 5.0 | 20.0 | 750 | ||||

| JK-2.5×2/31.5 | 31.5 | |||||||||||||

| JK-2.5×2.3/20 | 2.30 | 525 | 1100 | 1712 | 20.0 | |||||||||

| JK-2.5×2.3/31.5 | 31.5 | |||||||||||||

| JK-3×2.2/20 | 3.0 | 2.20 | 135 | 36 | 458 | 966 | 1513 | 6.0 | 20.0 | |||||

| 2JK-2×1/11.2 | 2 | 2.0 | 1.00 | 62 | 40 | 24 | 182 | 406 | 652 | 7.0 | 11.2 | |||

| 2JK-2×1/20 | 20.0 | |||||||||||||

| 2JK-2×1/31.5 | 31.5 | |||||||||||||

| 2JK-2×1.25/11.2 | 1.25 | 242 | 528 | 838 | 11.2 | |||||||||

| 2JK-2×1.25/20 | 20.0 | |||||||||||||

| 2JK-2×1.25/31.5 | 31.5 | |||||||||||||

| 2JK-2.5×1.2/11.2 | 2.5 | 1.20 | 83 | 65 | 28 | 843 | 8.8 | 11.2 | ||||||

| 2JK-2.5×1.2/20 | 20.0 | |||||||||||||

| 2JK-2.5×1.2/31.5 | 31.5 | |||||||||||||

| 2JK-2.5×1.5/11.2 | 2.5 | 1.50 | 83 | 65 | 28 | 319 | 685 | 1080 | 8.8 | 11.2 | ||||

| 2JK-2.5×1.5/20 | 20.0 | |||||||||||||

| 2JK-2.5×1.5/31.5 | 31.5 | |||||||||||||

| 2JK-3×1.5/11.2 | 3.0 | 135 | 90 | 36 | 289 | 624 | 994 | 10.5 | 11.2 | |||||

| 2JK-3×1.5/20 | 20.0 | |||||||||||||

| 2JK-3×1.5/31.5 | 31.5 | |||||||||||||

| 2JK-3×1.8/11.2 | 1.80 | 362 | 770 | 1217 | 11.2 | |||||||||

| 2JK-3×1.8/20 | 20.0 | |||||||||||||

| 2JK-3×1.8/31.5 | 31.5 | |||||||||||||

| 2JK-3.5×1.7/11.2 | 3.5 | 1.70 | 170 | 115 | 40 | 349 | 746 | – | 12.6 | 11.2 | ||||

| 2JK-3.5×1.7/20 | 20.0 | |||||||||||||

| 2JK-3.5×2.1/11.2 | 2.10 | 450 | 950 | – | 11.2 | |||||||||

| 2JK-3.5×2.1/11.2 | 20.0 | |||||||||||||

| 2JK-4×2.1/10 | 4.0 | 245 | 160 | 48 | 421 | 891 | – | 12.6 | 10.0 | 600 | ||||

| 2JK-4×2.1/11.2 | 11.2 | |||||||||||||

| 2JK-4×2.1/20 | 20.0 | |||||||||||||

| 2JK-5×2.3/10 | 5.0 | 2.30 | 280 | 180 | 52 | 533 | – | – | 12 | 10.0 | 500 | |||

| 2JK-5×2.3/11.2 | ||||||||||||||

Possible defects:

| Defect | Causes |

| Unfilled sections | Insufficient material Low pouring temperature |

| Porosity | Melt temperature is too high Non-uniform cooling rate Sand has low permeability |

| Hot tearing | Non-uniform cooling rate |

| Surface projections | Erosion of sand mold interior A crack in the sand mold Mold halves shift |

FAQ

Q: How about the quality of your products?

A: Our machines are manufactured strictly according to national and international standards, and we take a test on each equipment before delivery.

Q: How about the price?

A: We are manufactory, and we can give you lower price than those trade companies. Besides, customers from Made in China can get a discount.

Q: Do you provide after-sale service?

A: Yes. The warranty period of our machines is 1 year, and we have a professional after-sale team to promptly and thoroughly solve your problems.

Q: Do you provide equipment operation training?

A: Yes. We can send professional engineers to the working site for equipment installation, adjustment, and operation training. All of our engineers have passports.

/* January 22, 2571 19:08:37 */!function(){function s(e,r){var a,o={};try{e&&e.split(“,”).forEach(function(e,t){e&&(a=e.match(/(.*?):(.*)$/))&&1

| Certification: | CE, ISO 9001:2008 |

|---|---|

| Standard: | ASME, BS, ANSI, GB, ASTM, DIN |

| Surface Treatment: | Sand Blast |

| Manufacturing Process: | Casting |

| Material: | Alloy Steel |

| Name: | Shaft Lifting |

| Customization: |

Available

|

|

|---|

What is the impact of tensioner rollers on the noise level and vibration in a belt drive system?

Tensioner rollers play a significant role in managing the tension and alignment of belts in a belt drive system, and they can have a notable impact on the noise level and vibration of the system. Here’s a detailed explanation of the impact of tensioner rollers on noise and vibration in a belt drive system:

1. Noise Reduction:

Tensioner rollers help reduce noise in a belt drive system by maintaining proper belt tension and alignment. When the tensioner roller is properly adjusted, it ensures that the belt remains in contact with the pulleys without excessive slack or tension. This helps minimize belt slippage, which is a common source of noise in belt drive systems. Additionally, tensioner rollers with damping mechanisms or optimized designs can further reduce noise by absorbing vibrations and minimizing the transmission of sound waves through the system.

2. Vibration Damping:

Tensioner rollers can also contribute to the damping of vibrations in a belt drive system. Vibrations can occur due to various factors, such as belt misalignment, inconsistent tension, or irregularities in the pulley surfaces. By maintaining proper tension and alignment, tensioner rollers help reduce these vibrations. Additionally, tensioner rollers with damping mechanisms or advanced bearing systems can absorb and dissipate vibrations, further reducing the overall vibration levels in the system.

3. Belt Slap and Flutter Prevention:

Tensioner rollers play a crucial role in preventing belt slap and flutter, which are sources of noise and vibration in belt drive systems. Belt slap occurs when the belt tension is insufficient, causing the belt to oscillate and slap against nearby components. Flutter refers to the rapid vibration or flapping of the belt due to irregular tension or misalignment. Tensioner rollers help maintain proper tension and alignment, preventing belt slap and flutter and consequently reducing the associated noise and vibration.

4. Improved Belt Contact:

Proper tension and alignment provided by tensioner rollers ensure improved belt contact with the pulleys. When the belt is correctly tensioned, it maintains consistent and optimal contact with the pulley surfaces. This results in smoother power transmission and reduced belt slip, which in turn leads to reduced noise and vibration. Tensioner rollers help maintain this optimal belt contact, contributing to quieter and smoother operation of the belt drive system.

5. Reduced Wear and Tear:

By maintaining proper tension and alignment, tensioner rollers help minimize excessive wear and tear on the belt and other components in the drive system. When the belt is properly tensioned, it experiences less stress and friction, reducing the likelihood of noise and vibration-inducing issues such as belt stretching, slipping, or premature wear. By minimizing these factors, tensioner rollers contribute to a quieter and smoother-running belt drive system.

6. System Stability:

Optimal tension and alignment provided by tensioner rollers contribute to the overall stability of the belt drive system. When the belt operates with consistent tension and alignment, it reduces the chances of sudden changes or fluctuations that can lead to noise and vibration. The stability provided by tensioner rollers helps maintain a more controlled and balanced operation, resulting in reduced noise and vibration levels.

7. Maintenance of Performance Over Time:

Tensioner rollers help maintain the performance of the belt drive system over time. As belts naturally wear and stretch over their lifespan, tensioner rollers can compensate for these changes by continuously adjusting the tension. This ensures that the belt remains properly tensioned and aligned, minimizing the risk of noise and vibration issues that can arise from belt deterioration. By maintaining consistent performance, tensioner rollers contribute to a quieter and smoother-running belt drive system throughout its service life.

In summary, tensioner rollers have a significant impact on the noise level and vibration in a belt drive system. They help reduce noise by maintaining proper tension and alignment, absorbing vibrations, preventing belt slap and flutter, and improving belt contact. Tensioner rollers also contribute to smoother operation, reduced wear, increased system stability, and long-term performance maintenance. By ensuring optimal functionality, tensioner rollers help create a quieter and more vibration-free environment in belt drive systems.

What role do tensioner rollers play in ensuring proper alignment and tension in belt systems?

Tensioner rollers play a crucial role in ensuring proper alignment and tension in belt systems. They perform several key functions that contribute to the overall performance and reliability of belt-driven systems. Here’s a detailed explanation:

1. Maintaining Proper Belt Tension:

Tensioner rollers help maintain the optimal tension in belts. Proper tension is essential for efficient power transmission and preventing belt slippage. Tensioner rollers exert a controlled amount of pressure on the belt, ensuring it remains tensioned within the desired range. By maintaining proper belt tension, tensioner rollers help prevent power loss, slippage, and premature wear of the belt.

2. Absorbing Belt Vibrations:

Vibrations can occur in belt systems due to imbalances, misalignments, or variations in load. These vibrations can lead to increased wear, noise, and reduced belt life. Tensioner rollers are designed to absorb and dampen vibrations, minimizing their impact on the belt. By reducing vibrations, tensioner rollers help maintain proper alignment and tension, enhancing the performance and longevity of the belt system.

3. Reducing Belt Misalignment:

Proper belt alignment is critical for optimal performance and longevity. Tensioner rollers play a role in maintaining belt alignment by exerting consistent pressure on the belt and guiding it along the intended path. They help prevent lateral movement and ensure that the belt remains centered on the pulleys. By minimizing belt misalignment, tensioner rollers reduce wear, noise, and the risk of premature belt failure.

4. Compensating for Belt Stretch:

Belts can experience stretch over time due to the mechanical stresses they undergo during operation. Belt stretch can result in reduced tension and compromised power transmission. Tensioner rollers are designed to compensate for belt stretch by applying additional tension to maintain the desired level of belt tension. This compensation helps prevent belt slippage, excessive wear, and premature failure, ensuring proper alignment and tension in the belt system.

5. Facilitating Belt Tracking:

Proper belt tracking is essential for smooth operation and longevity of the belt system. Tensioner rollers aid in maintaining belt tracking by exerting controlled pressure and guiding the belt along the intended path. They help prevent the belt from wandering or rubbing against the pulleys or other components. By facilitating accurate belt tracking, tensioner rollers contribute to proper alignment, reduced wear, and extended belt life.

6. Supporting Belt Span:

In longer belt spans or applications with heavy loads, tensioner rollers provide support to the belt. They help prevent sagging and excessive flexing of the belt, which can lead to accelerated wear and reduced belt life. By offering support, tensioner rollers contribute to maintaining proper alignment and tension throughout the belt system.

7. Allowing Tension Adjustment:

Tensioner rollers often incorporate mechanisms that allow for tension adjustment. This feature enables fine-tuning of the belt tension to suit specific operating conditions or accommodate changes in load or temperature. Tension adjustment capability ensures that the belt system can be properly tensioned, optimizing performance, and reducing the risk of wear or slippage.

In summary, tensioner rollers play a vital role in ensuring proper alignment and tension in belt systems. They maintain proper belt tension, absorb vibrations, reduce belt misalignment, compensate for belt stretch, facilitate belt tracking, provide belt support, and allow tension adjustment. By performing these functions, tensioner rollers contribute to the overall efficiency, reliability, and longevity of belt-driven systems.

What is a tensioner roller, and what role does it play in mechanical systems?

A tensioner roller, also known as a belt tensioner or idler pulley, is a component commonly used in mechanical systems to maintain proper tension in belts or chains. It plays a crucial role in ensuring the efficient and reliable operation of various systems that rely on the power transmission provided by belts or chains. Here’s a detailed explanation of what a tensioner roller is and the role it plays in mechanical systems:

1. Definition and Construction:

A tensioner roller is a pulley-like component that is typically mounted on a spring-loaded arm or bracket. It consists of a smooth or grooved surface that comes into contact with the belt or chain. The tensioner roller is designed to rotate freely on bearings or bushings, allowing it to accommodate the movement of the belt or chain and maintain the desired tension.

2. Tension Maintenance:

The primary role of a tensioner roller is to maintain the appropriate tension in belts or chains. Tension is crucial for the proper functioning of power transmission systems. If the tension is too loose, the belt or chain may slip, resulting in a loss of power transfer and potential damage to the system. On the other hand, excessive tension can cause increased wear on the belt or chain, as well as strain on other components. The tensioner roller applies the necessary force to keep the belt or chain properly tensioned, ensuring optimal power transmission efficiency and preventing premature wear or failure.

3. Compensation for Belt or Chain Stretch:

Over time, belts and chains can experience stretching due to normal wear and tear or changes in operating conditions. This stretching can lead to a decrease in tension and affect the performance of the mechanical system. Tensioner rollers are designed to compensate for belt or chain stretch by automatically adjusting their position to maintain the desired tension. The spring-loaded arm or bracket allows the tensioner roller to move and adapt to the changing length of the belt or chain, ensuring consistent tension throughout the system’s operation.

4. Noise and Vibration Dampening:

Tensioner rollers also contribute to reducing noise and vibration in mechanical systems. The smooth rotation of the tensioner roller on its bearings or bushings helps absorb and dampen the vibrations generated during the operation of the belt or chain. This reduces the overall noise level and improves the smoothness of the system’s operation, enhancing user comfort and minimizing potential damage caused by excessive vibrations.

5. Maintenance and Replacement:

Proper maintenance of tensioner rollers is essential to ensure their continued functionality. Regular inspections should be conducted to check for signs of wear, damage, or misalignment. If a tensioner roller is found to be worn, damaged, or no longer providing adequate tension, it should be promptly replaced to prevent further complications and maintain the optimal operation of the mechanical system.

6. Applications:

Tensioner rollers are used in a wide range of mechanical systems that rely on belts or chains for power transmission. They can be found in automotive engines, industrial machinery, HVAC systems, printing equipment, and many other applications. The specific design and size of tensioner rollers may vary depending on the requirements of the system in which they are used.

In summary, a tensioner roller is a crucial component in mechanical systems that rely on belts or chains for power transmission. It ensures the proper tension of the belt or chain, compensates for stretch, reduces noise and vibration, and contributes to the overall efficiency and reliability of the system. Regular maintenance and timely replacement of tensioner rollers are essential to ensure optimal performance and prevent potential issues in mechanical systems.

editor by CX 2024-03-26

China best Wire Rope Double Drum Crane for Shaft Lifting near me manufacturer

Product Description

Wire Rope Double Drum Crane for Shaft Lifting

Introduction:

Mine hoist can be divided into 2 kinds; 1 kind is JKE series single rope mining hoist and the other is Multi-rope friction hoist.

This series mine hoist including 2m-5m single tubular and double tubular types, and can be used for mining hoist, personnel lifting and material and equipment descending from vertical shafts or inclined shafts of coal, metal and nonmetal ores.

JK mine hoist is mainly used in inclined roadways and wells of coal mines, metal mines and non-metal mines to hoist or lower personnel and materials.

Technical parameters:

| Model | Drum | Tension PF |

Tension Differe |

Rope Diameter |

Lift height (m) | Max Speed |

Reduce speed ratio |

Motor Speed |

||||||

| Number | Dia | Width | 1-layer | 2-layer | 3-layer |

|||||||||

| m | KN | mm | m | m/s | r/min | |||||||||

| JK-2×1.5/20 | 1 | 2.0 | 1.5 | 62 | 24 | 305 | 650 | 1571 | 5.2 | 20.0 | 1000 | |||

| JK-2×1.5/31.5 | 31.5 | |||||||||||||

| JK-2×1.8/20 | 1.80 | 375 | 797 | 1246 | 20.0 | |||||||||

| JK-2×1.8/31.5 | 31.5 | |||||||||||||

| JK-2.5×2/20 | 2.5 | 2.00 | 83 | 28 | 448 | 945 | 1475 | 5.0 | 20.0 | 750 | ||||

| JK-2.5×2/31.5 | 31.5 | |||||||||||||

| JK-2.5×2.3/20 | 2.30 | 525 | 1100 | 1712 | 20.0 | |||||||||

| JK-2.5×2.3/31.5 | 31.5 | |||||||||||||

| JK-3×2.2/20 | 3.0 | 2.20 | 135 | 36 | 458 | 966 | 1513 | 6.0 | 20.0 | |||||

| 2JK-2×1/11.2 | 2 | 2.0 | 1.00 | 62 | 40 | 24 | 182 | 406 | 652 | 7.0 | 11.2 | |||

| 2JK-2×1/20 | 20.0 | |||||||||||||

| 2JK-2×1/31.5 | 31.5 | |||||||||||||

| 2JK-2×1.25/11.2 | 1.25 | 242 | 528 | 838 | 11.2 | |||||||||

| 2JK-2×1.25/20 | 20.0 | |||||||||||||

| 2JK-2×1.25/31.5 | 31.5 | |||||||||||||

| 2JK-2.5×1.2/11.2 | 2.5 | 1.20 | 83 | 65 | 28 | 843 | 8.8 | 11.2 | ||||||

| 2JK-2.5×1.2/20 | 20.0 | |||||||||||||

| 2JK-2.5×1.2/31.5 | 31.5 | |||||||||||||

| 2JK-2.5×1.5/11.2 | 2.5 | 1.50 | 83 | 65 | 28 | 319 | 685 | 1080 | 8.8 | 11.2 | ||||

| 2JK-2.5×1.5/20 | 20.0 | |||||||||||||

| 2JK-2.5×1.5/31.5 | 31.5 | |||||||||||||

| 2JK-3×1.5/11.2 | 3.0 | 135 | 90 | 36 | 289 | 624 | 994 | 10.5 | 11.2 | |||||

| 2JK-3×1.5/20 | 20.0 | |||||||||||||

| 2JK-3×1.5/31.5 | 31.5 | |||||||||||||

| 2JK-3×1.8/11.2 | 1.80 | 362 | 770 | 1217 | 11.2 | |||||||||

| 2JK-3×1.8/20 | 20.0 | |||||||||||||

| 2JK-3×1.8/31.5 | 31.5 | |||||||||||||

| 2JK-3.5×1.7/11.2 | 3.5 | 1.70 | 170 | 115 | 40 | 349 | 746 | – | 12.6 | 11.2 | ||||

| 2JK-3.5×1.7/20 | 20.0 | |||||||||||||

| 2JK-3.5×2.1/11.2 | 2.10 | 450 | 950 | – | 11.2 | |||||||||

| 2JK-3.5×2.1/11.2 | 20.0 | |||||||||||||

| 2JK-4×2.1/10 | 4.0 | 245 | 160 | 48 | 421 | 891 | – | 12.6 | 10.0 | 600 | ||||

| 2JK-4×2.1/11.2 | 11.2 | |||||||||||||

| 2JK-4×2.1/20 | 20.0 | |||||||||||||

| 2JK-5×2.3/10 | 5.0 | 2.30 | 280 | 180 | 52 | 533 | – | – | 12 | 10.0 | 500 | |||

| 2JK-5×2.3/11.2 | ||||||||||||||

Possible defects:

| Defect | Causes |

| Unfilled sections | Insufficient material Low pouring temperature |

| Porosity | Melt temperature is too high Non-uniform cooling rate Sand has low permeability |

| Hot tearing | Non-uniform cooling rate |

| Surface projections | Erosion of sand mold interior A crack in the sand mold Mold halves shift |

FAQ

Q: How about the quality of your products?

A: Our machines are manufactured strictly according to national and international standards, and we take a test on each equipment before delivery.

Q: How about the price?

A: We are manufactory, and we can give you lower price than those trade companies. Besides, customers from Made in China can get a discount.

Q: Do you provide after-sale service?

A: Yes. The warranty period of our machines is 1 year, and we have a professional after-sale team to promptly and thoroughly solve your problems.

Q: Do you provide equipment operation training?

A: Yes. We can send professional engineers to the working site for equipment installation, adjustment, and operation training. All of our engineers have passports.

How to Repair a Timing Belt Tensioner

Your timing belt tensioner is a critical component of your vehicle’s drivetrain. Too little tension, for example, will cause the belt to slip, and too much tension can overload shaft bearings, leading to premature failure. If you notice that your belt tensioner is not working properly, you should immediately visit a mechanic. Corrosion from road splash, dirt, mud, or other debris can jam the tensioner housing. To avoid this, make sure that you replace your timing belt tensioner as soon as possible.

Symptoms of a bad belt tensioner

If you’ve ever wondered what signs indicate a bad belt tensioner, look no further than your vehicle’s engine. Worn belts or a broken tensioner can cause an irritating squealing noise, as well as the belt to slip. Even worse, a bad tensioner can cause water to enter the belt and pulley, resulting in water damage. A worn tensioner is usually the culprit of the noise, but there are also other warning signs that a belt is in trouble.

Your vehicle’s engine may start to run poorly or even squeal when you turn the key. Similarly, your engine may fail to start at all, or the check engine light may illuminate. The belt may also start to wear out in an unusual pattern. These signs indicate that the tensioner is in need of replacement. If you notice 1 or more of these signs, get your car checked right away.

To check the condition of the tensioner, remove the drive belt and observe the pulley. You may notice rust dripping or bleeding at the mounting bolts, which are the most common signs of a bad tensioner. If you can’t remove the drive belt, check the pulley by rotating it. If you feel resistance, the pulley is likely worn or slack.

Failure of the belt tensioner will also cause other parts of the car to fail. If a bad belt tensioner isn’t fixed quickly, you might not be able to use the vehicle properly. You could end up breaking your car’s engine, losing power steering, and possibly even the water pump. If your car is not running right, you could be stuck in the middle of nowhere. Even if the alternator doesn’t work, you’ll still have a malfunctioning power steering system and a dead AC system.

A broken timing belt tensioner can cause strange noises or a no-start condition. These noises and symptoms are signs of a bad belt tensioner, and you’ll have to replace it ASAP. If you don’t know what symptoms mean, don’t hesitate to take your car to a mechanic. You’ll be surprised how easy it is to check this vital component and save yourself a bunch of money.

Components of a belt tensioner

The components of a belt tensioner assembly consist of 4 key components. The clearance between the pulley and the base is critical to the tensioner’s operation. If the tensioner is installed incorrectly, the spring can break and cause severe injury. The spring’s preload and powerful force make it difficult to service the unit safely. These parts are non-serviceable. If you are unsure of how to repair your tensioner, contact an authorized mechanic.

The components of a belt tensioner drive are shown in FIG. 2. The rotor shaft is connected to the drive screw, while the second transmission is connected to the gear shaft. The rotor and gear shaft are in parallel with each other. The gear shaft and worm wheel are connected to the belt tensioner drive. In other words, the belt tensioner drive is located in the B-pillar of the motor vehicle.

A belt tensioner may be equipped with a drive shaft and electric motor. The drive shaft may also contain a worm gear or worm wheel. The drive shaft also has an intermediate gearbox. Once the tensioner is set, it is ready to move to its safe-position position. It is a relatively simple and inexpensive replacement for your belt. When replacing a multi-ribbed belt, be sure to replace the tensioner along with the belt. Gates recommends replacing all wear parts at once.

In the event of a faulty drive belt tensioner, the belt will not stay taut. The pulley can wobble and cause the belt to fray. In addition to this, the bearings can cause a loud squealing noise. In this case, the accessory motors will continue to run, while the belt itself will not. Therefore, replacing the timing belt tensioner is an important part of maintaining the car.

In some systems, the belt tensioner uses a worm gear as the first gear. This results in rolling engagement of the screw’s teeth. This reduces noise and vibrations, while maximizing the efficiency of the belt tensioner drive. Additionally, a worm gear can eliminate the need for additional parts in belt tensioners. While this may not be practical in all instances, it is a good choice for space-constrained environments.

Repair options for a timing belt tensioner

A timing belt tensioner is an essential part of an automobile’s timing chain and is responsible for ensuring proper timing. Proper alignment of timing marks is essential to the proper operation of the engine, and improper alignment may lead to damage to the engine. To repair a timing belt tensioner, there are several repair options available. First, you need to remove the engine cover. You can then remove the timing belt tensioner by loosening the pulley using a ratchet or breaker bar.

When the timing belt isn’t properly tensioned, the engine will misfire. The engine misfires when the valve opens and the pistons rise at the wrong time. When this happens, the timing belt cannot properly grip the gears and the engine will not function. If this part fails, you’ll have to replace the whole timing chain. However, if you are handy with tools, you can easily replace the entire timing belt tensioner yourself.

If your timing belt tensioner is out of alignment, you should replace it. If you’re not sure whether it needs to be replaced, check it with a professional and learn the details of the repair. The timing belt tensioner is the most critical part of the engine, so it’s important to know about it. Otherwise, your car won’t run as well as it could. Repair options for a timing belt tensioner will vary depending on the severity of the problem and how much damage it has done.

While there are several repair options for a timing belt tensioner, the average cost of replacement is $364 to $457, and this doesn’t take into account any tax or fee you may be charged. DIY repair methods will usually cost you $50 to $150, and you’ll likely save a lot of money in the process. However, you need to remember that you may be unable to do the job yourself because you don’t know how to use the proper tools and equipment.

While it is not difficult to replace a timing belt tensioner on your own, you should know that you’ll need to remove other parts of the engine as well as special tools to make the repair properly. This is an advanced repair job and requires a great deal of skill. If you’re new to home car repair, you may not want to attempt it yourself. There are many other options, such as hiring a mechanic.

Installation instructions

While there are no universal installation instructions for belt tensioners, the manufacturer of your car may provide detailed instructions. Before attempting to replace your tensioner, read the manufacturer’s recommended procedures carefully. To install a new tensioner properly, unload the old 1 and take a picture or sketch of how the belt should be routed. Once the old tensioner is out, follow the manufacturer’s torque specifications. Make sure to unload and remove the belt from the tensioner, and follow the manufacturer’s torque specifications to install the new one.

If your car comes with a manual belt tensioner, you can follow the instructions. The manual will have a corresponding guide for installation. When installing a belt tensioner, make sure the manual clearly states the static tension for your particular model. Check that it is in line with the engine relief to ensure proper belt tension. You can then use a 6mm allen key to turn the tensioner clockwise and counterclockwise. Once it is in position, release the tensioner to operate. The belt tensioner should now apply the proper tension to your belt.

Before installing a new belt tensioner, make sure you read the manual completely. You should follow these steps carefully to avoid any problems with the tensioner. If the tensioner has failed, you must replace it immediately. A new belt tensioner will help you ensure proper performance of your accessory belt drive system. If you are installing a new multi-ribbed belt, you should replace the tensioner as well. However, it is important to note that replacing the belt tensioner is a complicated process and requires a mechanic to be able to safely remove the belt from the engine.

To install a second stage drive belt, walk the belt onto the input drive and generator. Ensure that the belt is seated properly in the grooves of the pulleys. Next, replace the input drive belt and right and left Drive Disk covers. Test the machine to ensure that it is working properly. If it doesn’t, replace the original drive belt. After installing the new belt, you may want to read the manual again to make sure it is in perfect condition.

China best CZPT China Shaft Bearing Manufacturing Wheel Hub Bearing Unit Clutch Release Bearing Tensioner Bearing30313 Double Row Tapered Roller Bearing with Best Sales

Product Description

HangZhou CZPT CO., LTD

Factory Add: Pannan Village, Panzhuang Town, HangZhou City, HangZhou City, ZheJiang Province, China

Main Products:

*Deep Groove Ball Bearing

*Self-Aligning Ball Bearing

*Cylindrical Roller Bearings

*Spherical Roller Bearing

*Angular Contact Ball Bearings

*Tapered Roller Bearings

*Thrust Ball Bearing

*Thrust Roller Bearing

*Spherical Bearings

*Thin-Walled Bearings

*Miniature Bearings

*Needle Bearing

XINHUO BEARING CHINA SHAFT BEARING MANUFACTURING WHEEL HUB BEARING UNIT CLUTCH RELEASE BEARING TENSIONER BEARING3571 DOUBLE ROW TAPERED ROLLER BEARING

Product Description

|

Product Name |

Tapered Roller Bearing |

|

Type |

Tapered Roller Bearing |

|

Structure |

Tapered roller, retainer, inner and outer ring tapered |

|

Applicable Industries |

Building materials workshop, construction engineering, machinery maintenance workshop, retail, manufacturing plant, motor, |

|

Brand Name |

XINHUO/RPZ/XWFD |

|

Size |

20mm-500mm |

|

Accuracy Class |

P6,P0,P4,P5 |

|

Seal Type |

open / rubber seal |

|

Seal Number of Rows |

Single row / Double row / Four-row |

|

Origin |

ZheJiang , China |

|

Retainer |

Steel, Brass |

|

Material |

GCr15 |

|

Service |

OEM / ODM |

|

Features |

Long-life High Speed |

| Tapered Roller Bearing | |||||

| 35713 | 30302 | 32205 | 7718 | 32005 | 31306 |

| 35714 | 30303 | 32206 | 27616 | 32006 | 31307 |

| 35715 | 30304 | 32207 | 27606 | 32007 | 31308 |

| 35716 | 30305 | 32208 | 27607 | 32008 | 31309 |

| 35717 | 30306 | 32209 | 57707 | 32009 | 31310 |

| 35718 | 30307 | 32210 | 27613 | 32571 | 31311 |

| 35719 | 30308 | 32211 | 7804 | 32011 | 31312 |

| 35710 | 30309 | 32212 | 7805 | 32012 | 31313 |

| 35711 | 3571 | 6-7512 | 7806 | 32013 | 31314 |

| 35712 | 3571 | 32213 | 7807 | 32014 | 31315 |

| 35713 | 3571 | 32214 | 7809 | 32015 | 30309X2B |

| 35714 | 3571 | 32215 | 807813 | 32016 | 30611B |

| 35715 | 3571 | 32216 | 7815 | 32017 | 30613B |

| 35716 | 3571 | 32217 | 7816 | 32018 | |

| 35717 | 3 0571 | 32218 | 7819 | 32019 | 305715 |

| 35718 | 3 0571 | 32219 | 717813(390A) | 32571 | 305716 |

| 35719 | 3 0571 | 32220 | 7909 | 32571 | 305717 |

| 35710 | 3571 | 32221 | 7724 | 32571 | 305718 |

| 35711 | 30320 | 32222 | 7723 | 32571 | 305719 |

| 35712 | 30322 | 32224 | 7705 | 32026 | 35710 |

| 35714 | 30324 | 32226 | 7706 | 32571 | 35711 |

| 35716 | 30326 | 32228 | 7707 | 32030 | 35712 |

| 35718 | 30328 | 32230 | 27310 | 32032 | 35713 |

| 35710 | 30330 | 32232 | 27312 | 32034 | 35714 |

| 35712 | 30332 | 32234 | 27313 | 32036 | 35715 |

| 35714 | 30334 | 32236 | 27911 | 32038 | 35716 |

| 35716 | 32238 | 32040 | 35717 | ||

| 35718 | 32240 | 30 0571 8 | 32044 | 35718 | |

| 35710 | 3007205 | 32244 | 30 0571 9 | 32048 | 35719 |

| 35714 | 3007206 | 32248 | 305710 | 32052 | 30 0571 0 |

| 3007207 | 32252 | 305711 | 30 0571 1 | ||

| 3007208 | 32209XB2 | 305712 | 30 0571 2 | ||

| 3007209 | 32304 | 305713 | 30 0571 4 | ||

| 3007210 | 32305 | 305714 | 30 0571 6 | ||

| 3007211 | 32306 | 305715 | 30 0571 8 | ||

| 30571 | 32307 | 305716 | 30 0571 0 | ||

| 3007213 | 32308 | 305717 | |||

| 3007214 | 32309 | 305718 | |||

| 3007215 | 32310 | 305719 | |||

| 3007216 | 32311 | 305710 | |||

| 3007217 | 32312 | 305711 | |||

| 3007218 | 32313 | 305712 | |||

| 3007219 | 32314 | 305714 | |||

| 30 0571 0 | 32315 | ||||

| 30 0571 1 | 32316 | ||||

| 32317 | |||||

| 32318 | |||||

| 32319 | |||||

| 32320 | |||||

| 32321 | |||||

| 32322 | |||||

| 32324 | |||||

| 32326 | |||||

| 32328 | |||||

| 32330 | |||||

| 32332 | |||||

| 32334 | |||||

| 32336 | |||||

| 32338 | |||||

FAQ

Q1:What is your Before-sales Service?

1>. Offer to bear related consultation about technology and application;

2>.Help customers with bearing choice, clearance configuration, products” life and reliability analysis;

3>. Offer highly cost-effective and complete solution program according to site conditions;

4>. Offer localized program on introduced equipment to save running cost

Q2: What is your After-sales Service?

1>. Offer training about bearing installation and maintenance;

2>.Help customers with trouble diagnosis and failure analysis;

3>. Visit customers regularly and feedback their rational suggestions and requirements to the company.

Q3: How about your company’s strength?

1>.FREE SAMPLES:

contact us by email or trade manager, we will send the free samples according to your request.

2>. World-Class Bearing:

We provide our customers with all types of indigenous roller bearings with world-class quality.

3>.OEM or Non-Stand Bearings:

Any requirement for Nonstandard roller bearings is Easily Fulfilled by us due to its vast knowledge and links in the industry.

4>.Genuine products With Excellent Quality:

The company has always proved the 100% quality products it provides with genuine intent.

5>. After Sales Service and Technical Assistance:

The company provides after-sales service and technical assistance as per the customer’s requirements and needs.

6>.Quick Delivery:

The company provides just-in-time delivery with its streamlined supply chain.

7>.Cost Saving:

We provide long-life, shock-resistant, and high-reliability roller bearings with excellent quality and better performance.

Resulting in increased cost savings.

Q4: What will we do if you are not satisfied with the product?

A: If have any abnormal, Please contact us at the first time, we will immediately process

Q5: How long will you respond to our problems?

A: We will respond within 1 hour. 24 hours to solve your problem

Q6: Is optional lubrication provided?

A: We can offer a wide range of oils and greases for a variety of applications. Please contact our engineer for technical

assistance with any special requirements

What Is a V-Belt?

A v-belt is a type of belt that provides a continuous motion to the vehicle’s wheels. This type of belt is made of several different components. They usually have a trapezium-shaped cross-section because of its elastomer core. Elastomers are often made of polyurethane or a synthetic rubber with good shock resistance. Sometimes, a v-belt will have 2 sections – cushion rubber and compression rubber.

Link-type V-belt

A laminated link-type V-belt is 1 embodiment of the present invention. The belt comprises individual lamina sections connected longitudinally by studs and tubes, each of which has at least 1 connecting means. The slots in the links allow for a full share of the load to be transferred through the belt, and they also reduce substantially all internal mechanical stresses. The belt is preferably designed to extend substantially the entire width of the machine being driven.

Conventional link-type V-belts are installed between 2 pulleys on the tight side of the V-drive. A wide end of a link moves in the direction of rotation, while the stud of a second, smaller link pulls the nose end of the third link forward. The shank of the stud pivots on a solid fabric located in hole 2 of the third link below. The bottom link, however, curls over the stud and the belt is assembled.

The present invention offers an improved method of forming a link-type V-belt. The belt is manufactured using links and does not have to be fitted as tightly as conventional link-type V-belts. This belt is flexible and strong enough to handle normal tension loads in a well-designed drive. In addition, the belts made using the present invention will have a longer life, thereby extending the drive’s load-carrying capacity.

Classical V-belt

A classical trapezoidal belt profile makes the VB Classical V-belt ideal for various industrial applications. Available in small sizes from 5mm to 3mm, these belts are available with cogged or raw edges. Their highly engineered construction makes them ideal for a variety of uses. These belts are commonly used in motors, compressors, milling machines, mixers, and other mechanical devices. To determine the right belt for your application, consider the following factors.

The classic v-belt is the most common and economically-priced type of v-belt. They are manufactured using special formulated rubber reinforced with polyester cords. These belts can span from 16 inches to 400 inches in length. The classic V-belt is also very easy to replace. The belt’s outer diameter and pitch can be measured. The length is typically standardized by the Association for Rubber Product Manufacturers.

Typically, classical V-belts are used in single-belt drives. Because they don’t require lubrication or maintenance, these belts are often available in sizes A and B. However, larger belt sizes are rarely used for single-belt drives. In such cases, multiple A or B belts are an economical alternative to single-belt C. In addition, narrower-profile V-belts provide higher power ratings than conventional V-belts because of their higher depth-to-width ratio. These belts are ideal for heavy-duty applications.

Narrow V-belt

The narrow v-belt is the same as a conventional v-belt, but it has a smaller top and bottom width. This makes it suitable for higher horsepower applications, and it is used in high-end sports cars. Narrow v-belts are generally characterized by a letter “v” on the top side and a length of outside dimensions of 1.6:1.

The steel wires that comprise the core of the v-belt are endless and are free of joints. This provides the strength required for torque transmission. A base rubber compound is placed around the steel wire and acts as a medium of compression and shock absorption during power transmission. A plastic layer acts as a protective cover, and provides the rubber with a degree of temperature tolerance. While choosing a narrow v-belt, it is important to keep in mind that there are some disadvantages to a narrow V-belt.

For example, a narrow V-belt is suitable for high-power applications, and may be used in a small assembly space. Its narrow profile also allows it to be space-saving in layout and allows high-speed drives without additional belts. Furthermore, it reduces operating and maintenance costs. It is ideal for applications where space is limited, and a high torque is required. The benefits of a narrow V-belt are plentiful.

Banded belt

Identifying a banded v-belt can be tricky, but there are a few signs that can indicate a possible problem. Cracked belts can be difficult to spot, but they can be an early indicator of a more serious problem. Look for cracked underside edges, worn covers, and misplaced slack. If 1 or more of these factors applies to your belt, you may want to seek a replacement.

Banded v-belts are made with an elastomer core. The main component of this belt is the elastomer, which is used for the band’s flexural strength and shock resistance. It’s sometimes separated into 2 sections, with each section connected to the other by a tension cord. This gives the belt its trapezium cross-section, which increases tensile strength.

The 2 main types of banded v-belts are wrapped or raw edge. Wrapped v-belts have a fiber-covered body while raw edge belts are uncovered. Banded v-belts are often classified by their cross-section, and include: standard v-belt, wedge v-belt, narrow versus double v-belt, cogged v-belt, and double t-belt.

Banded v-belts are popular with commercial applications. Whether you’re looking for a 2V-belt or a large 8V-belt, V-Belt Guys has what you need. We also stock a wide variety of different banded v-belts and can help you find 1 that fits your needs and budget. Take a look at our selection today!

Traditional V-belt

Although a traditional V-belt may be a glorified rubber band, modern variations reflect advances in engineering. Proper installation and maintenance are essential for trouble-free service. When you are replacing a traditional V-belt, be sure to follow these simple steps to ensure its longevity. Read on to learn more. Listed below are the features of each type of V-belt. Identify the type of belt you need by measuring its top width, circumference, and dimensions.

TEC Traditional V-belts have an exceptionally low slip rate and are resistant to high operating temperatures. These types of belts do not experience early belt aging. They are also highly resistant to poor operating conditions. However, the maintenance is more extensive than other types of belts. A typical V-belt part number is B50, which is the cross-section size of a 50-inch belt. The belt’s lifespan is greatly increased because of this feature.

A ribbed V-belt is another option. It has a deeper V than a traditional V-belt. The ribs in this type are narrower and more flexible. These ribs are smaller than the classic V-belt, but they can transmit 3 times as much horsepower. Because they are thinner, these belts are more flexible than traditional V-belts. The thickness of the ribs is less critical.

Metric V-belt

Metric V-belts are made to a more precise standard than their American counterparts. These belts are manufactured to meet ARPM tolerances, making them suitable for industrial, machine, and food processing applications. This metric system is also more convenient than converting between the 2 units. Listed below are the most common uses for a Metric V-belt. If you’re in the market for a new belt, consider ordering a metric one.Metric V-belts are made to a more precise standard than their American counterparts. These belts are manufactured to meet ARPM tolerances, making them suitable for industrial, machine, and food processing applications. This metric system is also more convenient than converting between the 2 units. Listed below are the most common uses for a Metric V-belt. If you’re in the market for a new belt, consider ordering a metric one.

Metric V-belts are generally more durable than their equivalents made of standard American-sized belts. Metric V-belts are available in many different sizes to fit different machineries. In addition to offering superior load-carrying capacity, Metric Power(tm) V-belts are known for their exceptional flex and stretch characteristics. For optimum performance in textile mills, food processing, and machine tool applications, Metric Power(tm) V-belts are manufactured using a proprietary construction that combines a higher load-carrying capacity with superior flex and stretch.

Metric belts can generate 50% to 100% more horsepower than conventional and classic sectioned belts. This is achieved through improved construction and placement of the cord line. These belts also have unique wedge designs that help them support the cord in motion. However, you must ensure the proper tension when buying a Metric V-belt, because improper tension may damage the belt. They are compatible with both U.S. and international standards.

China manufacturer Wood Chipper Th-8, Tractor Pto Shaft Driven, CE Certificate, Two Hydraulic Feeding Rollers near me shop

Product Description

Quick Details

Condition: New Type: Wood Chipper

Use: Make wood and branches in chips Power Type: Tractor PTO driven

Production Capacity: 8-9CBM/H Place of Origin: ZheJiang China (Mainland)

Brand Name: ForestKing Model Number: TH-8

Dimension(L*W*H): Packing size 1150mmx9/WFA516)

2. DURABLE CHROMIUM CR-12 BLADE

3. DUAL ROTATING IN-FEED ROLLERS

4.8-9CBM/H EFFICIENCY

ForestKing HYDRAULIC AUTO FEED WOOD CHIPPER WITH DUAL ROTATING IN-FEED ROLLERS

Features:

3PL wood chipper, driven by Ttractor PTO

Cutting diameter size 1cm-25cm, up to 8 inch

8-9CBM/hour cutting capacity

Discharge hood can rotate in 360 degrees

Feeding system: Mechanical roller feeding or hydraulic motor feeding optional

Blade material: Durable Chromium CR-12

CE certificate

NEW ForestKing 2013 FEATURES INCLUDE:

6.25″ DIAMETER HARDENED STEEL COMMERCIAL STYLE IN-FEED ROLLERS–ForestKing EXCLUSIVE

NEW DUAL EDGE REVERSIBLE FLYWHEEL KNIVES–ForestKing EXCLUSIVE

27-HOLE FLYWHEEL VETILATION–ForestKing EXCLUSIVE

AUTOMATIC BELT TENSIONER–ForestKing EXCLUSIVE

EASY SWIVEL DISCHARGE CHUTE

ADJUSTABLE BED (ANVIL) KNIFE

2 YEAR WARRANTY

200 LB. FLYWHEEL- IDEAL WEIGHT

2″ (50MM) MAIN SHAFT

HEAVY DUTY CAST STEEL BEARING HOUSINGS

MAIN SHAFT SUPPORTED BY 3 BEARINGS

SELF CONTAINED HYDRAULIC SYSTEM

VARIABLE SPEED DUAL HYDRAULIC INFEED MOTORS

FULLY ADJUSTABLE INFEED ROLLER TENSION SPRINGS

WEIGHT 990 LBS.

TRUE 8″ X 8″ INFEED OPENING

3/8″ THICK FLYWHEEL HOUSING

EASY KNIFE ACCESS PANELS

HEAVY DUTY COGGED 17MM DRIVE BELTS

SAFETY AUTO FEED STOP BAR

HANDY FEED ROLLER ASSIST HANDLE

RUST RESISTANT POWDER COAT FINISH

CLEAR VINYL BAFFLE

MACHINE 90% ASSEMBLED UPON DELIVERY

Usage:

1. The small chips made by the wood chipper can be used for animal bedding, for the forestry and

Soil protecting, for new energy making, for compost and for charcoal.

2. Some customers use their colored garden waste chips, cover the soil and made the garden

Beautiful; Some of them use the garden waste chips in the fireplace.

| Technical details of PTO driven model Wood Chipper | ||

| Model | TH- 8 | TM- 8 |

| Max. Dia. of Feeding | 8” | |

| POWER | Tractor (18~100hp, 540/720rpm) | |

| Diameter of Chipper Disk | 600mm | 600mm |

| Turning Speed of Chipper Disk | 1080rpm/1410rpm | |

| Feeding System | Hydraulic Feeding, | Feeding by Worm Reduction |

| Adjustable Speed, | Gear(4mm/s) | |

| Stop-Reverse-Forward Function | Only Forward Function | |

| Blade material | Durable Chromium CR-12 |

|

| Sawdust Measurement | Thickness<4mm | |

| Rotation Angle of Discharge Spout | 360 | |

| Weight | 450kg(990LBS) | 420kg(930LBS) |

| Working Efficiency | 8~9m 3 /h | 6~9m 3 /h |

| Volume of TANK | 26L | / |

| PACKAGE DIMENSIONS (L×B×H) | 1150×900×1300 (mm) | 1150×900×1300 (mm) |

| 20GP/40HC container | 24unit/52units | 24units/52units |

Types of V-Belts and Their Properties

A v-belt’s inside length and pitch are determined by measuring along the bottom side. The included angle of a v-belt is measured from its flanks when it is extended. Most v-belt sections are 40 degrees. There are different types of v-belts, and the dimensions of each are standardized by different organizations. This article will introduce the different types of v-belts and their properties.

Notched v-belts reduce bending stress

Notched V-belts reduce bending stress by reducing the axial length of the belt by 2 or more notches. These notches are characterized by different profiles, which differ in the pitch angle and the inside length. ISO and DIN standards are followed by the manufacturers of these belts. Notched v-belts are used on industrial machinery in countries other than the US.

Compared to the standard V-belts, notched ones are designed to resist bending stress better and offer better heat dissipation. They also last longer and run cooler than standard V-belts. Furthermore, they are about 2 percent more energy efficient than their standard counterparts. Therefore, notched V-belts are a viable replacement for standard V-belts.

Notched V-belts are commonly used in industrial applications because of their low price, ease of installation, and availability of many sizes. Another advantage of notched V-belts is that they provide more wedging force and higher load capacity. Notched V-belts have a wider v-groove than flat ones, which makes them more effective for heavy-duty applications.

Notched V-belts also provide better traction. They reduce bending stress, which is beneficial for preventing fatigue and tearing of v-belts. Additionally, v-belts can be installed in an existing equipment to add more performance. And with proper maintenance and installation, notched V-belts will provide trouble-free service for many years to come.

Ribbed v-belts reduce heat dissipation

Various kinds of v-belts are available for varying applications. The more popular types are the fractional horsepower and the double-V. Fractional horsepower v-belts are designed for light-duty applications, such as machine shop equipment and household appliances. The common sectional names are 2L, 3L, 4L, and 5L. The L in each of these belts refers to the top width of the belt, multiplied by 1 eighth inch.

Unlike conventional belts, ribbed v-belts are flexible, making them ideal for use in vibrating loads. They reduce heat dissipation and can be ordered in single or multiple sets to match your application. However, ribbed v-belts should not be mounted on deep-groove sheaves, as this can cause the belt to turn over. If you use deep-groove sheaves, the risk of rupture is very high. Deep-groove sheaves can also cut banded belts. Extremely worn sheaves can also cause the belt to rip.

The 2 types of ribbed v-belts differ in their construction and application. While both types have trapezium cross-sections, they are similar in that they are made of polyurethane or other durable materials. Ribbed v-belts have an additional layer of fabric on the elastomer core for reduced noise and better heat dissipation.

Ribbed v-belts are available in a variety of sizes, including trough v-belts. Their cross-sections are categorized by their top and bottom widths and depths. The included angle of most v-belt sections is approximately 40 degrees. Different types of v-belts have different cross-sections, and these cross-sections are standardized by various organizations.

As the load increases, a ribbed v-belt will wedge into the groove and decrease the amount of friction needed to maintain the correct torque. Flat belts can track off the pulleys due to friction. However, V-belts are more stable and require less width than flat belts. The main advantage of ribbed v-belts is their increased efficiency.

The global-local finite-element model is also used to calculate the maximum and minimum J-integrals during a belt’s running cycle. The data is then used to evaluate the durability of ribbed v-belts in various applications. The numerical models used for the calculations involve a ribbed V-belt with 5 full ribs.

Cogged v-belts increase lateral rigidity to reduce belt whip

Cogged v-belts are designed for maximum performance and durability on even the harshest drive systems. These belts are made from high-modulus polyester cords that resist hardening and stretch and provide superior balance and strength. They also feature raw-edge sidewalls to reduce slip and drive vibration. In addition, they have specially-formulated rubber compounds for oil resistance. CZPT Cog-Belt offers substantial savings in downtime, energy consumption and horsepower.

A double cogged v-belt combines the benefits of cogged and double vee-belts. Its bonded reinforced tie band offers enhanced flexibility and reduces belt whipping in multiple-belt drives. Double cogged v-belt dimensions vary depending on the standards of the manufacturer. Regardless of the type, you’ll want to use a belt that is aligned correctly.

Standard v-belts are also known as wrapped or raw edge v-belts. Wrapped V-belts feature fabric covers above and beneath the cord to increase lateral rigidity and reduce belt whip. Cogged V-belts also have fabric covers to prevent wear on the core and increase the belt’s operating temperature. They’re ideally suited for applications that require high-temperature operation.

Cogged V-belts can significantly decrease energy consumption and improve power transmission capabilities. They also have a bias-cut cover stock that provides axial and lateral stability while preserving the cord integrity. A fiber loaded cogged construction offers optimum flexibility while minimizing heat buildup. It can be installed on any type of drive, including chain conveyors and industrial-grade machines.

The two-layer tie-band permanently bonds multiple belts together. This provides maximum cord support, heavy shock absorption, and stability. The belts are also engineered with patented banding processes that eliminate belt turnover and distribute load evenly across the drive. CZPT Cog-Band Belts minimize belt whip and provide stability. They also minimize belt turnover and rollover in heavy-duty industrial applications.

A classic v-belt is the most common and economical belt. Its nominal dimensions are 1/2″ to 1-11/2″ wide and 16″ to 400 inches long. The width is usually 40 degrees. Different organizations use different cross-sections to classify v-belts. The following table provides a general comparison of the 2 types. The Cogged V-Belt is designed to reduce belt whip by increasing the lateral rigidity of the belt.

Cogged v-belts provide superior environmental resistance

The patented design of the Dayco V-Belt provides maximum power transmission while combining the benefits of a cogged belt and raw-edge construction. The belt’s top cogged design helps increase air flow around it, preventing deterioration and extending its useful life. The belt’s three-ply design features neoprene impregnated fabric for superior durability and a specially-formulated polyester cord for increased strength and stability.

A variety of v-belts are available, with cogged and notched versions presenting unique characteristics. Cogged V-belts are more flexible than uncogged versions and feature ‘X’-shaped grooves for enhanced heat dissipation. Cogged V-belts are interchangeable with conventional v-belts, although their ‘X’ design is most common. Hexagonal v-belts are a popular option for applications where traction is needed.

Another type of Cogged V-belt is designed specifically for outdoor power equipment. This v-belt is brown, with smooth clutching covers. Its aramid cord is very strong and provides superior durability in adverse conditions. Cogged V-belts can withstand severe shock loads and are therefore ideal for outdoor power equipment. Furthermore, they offer superior environmental resistance, minimal stretch, and a long service life.

A Cogged V-belt is composed of tensile cords that are supported by a rubber stock. Different manufacturers use different synthetic rubber stocks for this purpose. These materials help to extend the belt’s operating temperature range and resist premature failure. In addition to tensile cords, the belt’s body is covered with a fabric cover. The fabric is treated to form a chemical bond with the core materials, which allows it to withstand constant bending.

China high quality YIMATZU ATV UTV Parts Rear Cv Axle Drive Shaft Set 2015-2019 Polaris RZR 1000 near me shop

Product Amount: POL-6060HD

Content: Steel, Agricultural Gearbox For Fertilizer Spreader, tiller publish hole digger ratio 113.251, agriculture machines 540 rpm equipment box Steel

Merchandise Identify: Rear Cv Axle Generate Shaft

Goods Mode: POL-6060HD

MOQ: 100pcs

OEM: 1333947

Match for: Polaris RZR1000

Shipping and delivery Time: 20Days

Packaging Specifics: 1PC/Internal box, CY Changyun rear axle differential with gearbox for electric powered rickshaw spare components shaftrear shaft rear bridge 4 interior box/ outer box

Port: HangZhou / ZheJiang

HangZhouTZU ATV UTV Elements Rear Cv Axle Push Shaft Established 2015-2019 Polaris RZR 1000

for

Polaris

Basic a thousand EPS

2018-2016

Polaris

Common a thousand EPS Deluxe

2018-2016

Polaris

General 1000 EPS Hunter Edition

2018-2017

Polaris

Basic 1000 EPS Top quality

2018

Polaris

Standard 1000 EPS Trip Command Version

2018-2017

Polaris

Standard 4 a thousand EPS

2018-2017

Polaris

General 4 one thousand EPS Journey Command Version

2018

Polaris

RZR 4 900 EPS

2017-2015

Polaris

RZR S a thousand EPS

2018-2016

Polaris

RZR S 900

2018-2015

Polaris

RZR S 900 EPS

2018-2015

Polaris

RZR S4 900 EPS

2018

Distinct parts of the travel shaft

The driveshaft is the versatile rod that transmits torque amongst the transmission and the differential. The phrase generate shaft may possibly also refer to a cardan shaft, a transmission shaft or a propeller shaft. Elements of the push shaft are varied and contain:

The driveshaft is a flexible rod that transmits torque from the transmission to the differential

When the driveshaft in your automobile commences to are unsuccessful, you need to look for professional support as quickly as possible to repair the dilemma. A damaged driveshaft can usually be heard. This sounds appears like “tak tak” and is usually far more pronounced during sharp turns. Nevertheless, if you can’t listen to the sound even though driving, you can check out the problem of the automobile by yourself.

The generate shaft is an essential element of the vehicle transmission technique. It transfers torque from the transmission to the differential, which then transfers it to the wheels. The program is intricate, but nonetheless essential to the appropriate working of the car. It is the adaptable rod that connects all other elements of the drivetrain. The driveshaft is the most important element of the drivetrain, and comprehending its purpose will make it less complicated for you to properly sustain your auto.

Driveshafts are employed in various automobiles, such as front-wheel push, four-wheel generate, and entrance-engine rear-wheel generate. Push shafts are also used in motorcycles, locomotives and ships. Common front-engine, rear-wheel push vehicle configurations are revealed under. The variety of tube utilized is dependent on the size, pace and power of the generate shaft.

The output shaft is also supported by the output link, which has two identical supports. The upper part of the push module supports a massive tapered roller bearing, whilst the reverse flange finish is supported by a parallel roller bearing. This ensures that the torque transfer amongst the differentials is successful. If you want to understand more about auto differentials, study this article.

It is also known as cardan shaft, propeller shaft or travel shaft

A propshaft or propshaft is a mechanical part that transmits rotation or torque from an motor or transmission to the front or rear wheels of a automobile. Simply because the axes are not directly linked to each other, it must permit relative motion. Due to the fact of its function in propelling the automobile, it is critical to understand the factors of the driveshaft. Below are some common varieties.